Schneider Electric, the global specialist in energy management, has helped New Belgium Brewing Company dramatically increase production using its Wonderware MES Performance software. Based in Fort Collins, Co., New Belgium Brewing emphasizes eco-friendly production practices, continuous improvement and metrics measurement. Just as it is vigilant about the products that go into its premium beers, the brewer also believes it is vital to have and maintain production processes that are as accurate, green and lean as possible.

Schneider Electric, the global specialist in energy management, has helped New Belgium Brewing Company dramatically increase production using its Wonderware MES Performance software. Based in Fort Collins, Co., New Belgium Brewing emphasizes eco-friendly production practices, continuous improvement and metrics measurement. Just as it is vigilant about the products that go into its premium beers, the brewer also believes it is vital to have and maintain production processes that are as accurate, green and lean as possible.

After a closer look at its bottling lines, the brewer’s operations management team realized they were producing 150,000 cases of beer each week on lines that were capable of producing 294,000. Scheduled and unscheduled downtime was causing valuable packaging time to be lost.

“After ramping up our bottling line to meet growing customer demand, we were disappointed to find the brewery was producing only about half of what it was truly capable of producing,” said Joe Herrick, packaging systems manager, New Belgium Brewing. “Our brewery’s existing manual systems generated a huge amount of data but we had no way of presenting it in context.”

To address these issues and to otherwise improve performance, New Belgium Brewing, with technical assistance from Apex Manufacturing Solutions, implemented a solution using Wonderware manufacturing execution system software from Schneider Electric. Not only does the Wonderware MES software track and record the bottling process automatically, it transforms raw data into user-friendly presentations that drive improvement. For example, the software facilitates shift changes by providing new workers with data on the performance of the previous shift. The system also integrates with the brewery’s existing Wonderware System Platform and Wonderware HMI software. The combined solutions improved operators’ ability to maintain precise packaging production schedules and effectively manage the materials supply chain during the brewing process.

“The ability to customize the graphics provided by the Wonderware MES software solution enabled us to develop a system that could effectively communicate the line status and production capacities of the bottling and packaging lines, while at the same time illustrate New Belgium’s unique company culture with engaging graphics,” said Sam Vail, chief strategy officer at Apex. “Screen data shows what order is being worked on, what is coming next and how the current rate compares to their standard. This is a great example of how Wonderware software changed the game for New Belgium Brewing, effectively enabling them to increase capacity, expand production and improve quality without investing in new equipment.”

“With Wonderware MES Performance software coupled with our continuous improvement strategy, we have increased the efficiency of our packaging line by 30 percent, which allowed us to extend our packaging capacity to about 1.3 million barrels each year,” Herrick said. “Improved manufacturing efficiencies plus increased line production means we’ve saved more than $400,000 in previously planned labor costs and decreased downtime by 50 percent. At this point, our approach to higher volumes is ‘bring it on.’

New Balance Laufschuhe und Bekleidung online kaufen

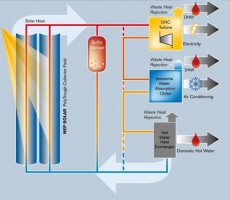

Case Study: NEP Solar developed, manufactures, and supplies the PolyTrough, a patented parabolic trough solar collector. NEP Solar also provides consulting services and delivers projects from conceptual design through to turnkey supply of solar thermal systems. Industrial heating is NEP Solar's key market where heat, normally generated by burning fossil fuels, is replaced with heat captured from the sun. The typical temperature is up to 250° C, although higher temperatures are possible.

Case Study: NEP Solar developed, manufactures, and supplies the PolyTrough, a patented parabolic trough solar collector. NEP Solar also provides consulting services and delivers projects from conceptual design through to turnkey supply of solar thermal systems. Industrial heating is NEP Solar's key market where heat, normally generated by burning fossil fuels, is replaced with heat captured from the sun. The typical temperature is up to 250° C, although higher temperatures are possible.

Schneider Electric, the global specialist in energy management, has helped New Belgium Brewing Company dramatically increase production using its Wonderware MES Performance software. Based in Fort Collins, Co., New Belgium Brewing emphasizes eco-friendly production practices, continuous improvement and metrics measurement. Just as it is vigilant about the products that go into its premium beers, the brewer also believes it is vital to have and maintain production processes that are as accurate, green and lean as possible.

Schneider Electric, the global specialist in energy management, has helped New Belgium Brewing Company dramatically increase production using its Wonderware MES Performance software. Based in Fort Collins, Co., New Belgium Brewing emphasizes eco-friendly production practices, continuous improvement and metrics measurement. Just as it is vigilant about the products that go into its premium beers, the brewer also believes it is vital to have and maintain production processes that are as accurate, green and lean as possible. Telemetry SCADA deployment can effectively use OPC provided that the driver’s SCADA engine properly handles the unique wireless telemetry communication requirements. Traditionally, SCADA (Supervisory Control and Data Acquisition) deployment has always used proprietary software applications and drivers to enable control centers to effectively manage the large amount of data collected. With the introduction of OPC, there have been various attempts at applying industrial standards to these SCADA based implementations.

Telemetry SCADA deployment can effectively use OPC provided that the driver’s SCADA engine properly handles the unique wireless telemetry communication requirements. Traditionally, SCADA (Supervisory Control and Data Acquisition) deployment has always used proprietary software applications and drivers to enable control centers to effectively manage the large amount of data collected. With the introduction of OPC, there have been various attempts at applying industrial standards to these SCADA based implementations. Kepware Technologies, a software development company focused on communications for automation, announced today that Cascades Tissue Group has implemented KEPServerEX and LinkMaster to improve connectivity across its diverse and sprawling infrastructure. Since adopting Kepware's communication solutions, Cascades Tissue Group has improved connectivity between modern and legacy machines, and increased operational efficiency by more than 5 percent.

Kepware Technologies, a software development company focused on communications for automation, announced today that Cascades Tissue Group has implemented KEPServerEX and LinkMaster to improve connectivity across its diverse and sprawling infrastructure. Since adopting Kepware's communication solutions, Cascades Tissue Group has improved connectivity between modern and legacy machines, and increased operational efficiency by more than 5 percent.