“The elimination of manual operations for the measurement of OEE parameters has resulted into significant cycle time reduction. Based on the results achieved with this solution, we are considering its extension to other countries outside Europe.”

“The elimination of manual operations for the measurement of OEE parameters has resulted into significant cycle time reduction. Based on the results achieved with this solution, we are considering its extension to other countries outside Europe.”

Stuttgart and Munich, Germany— BSH Boschund Siemens Hausgeräte GmbH, a joint venture between Robert Bosch GmbH in Stuttgart and Siemens AG in Munich since 1967, is a global group with approximately 9 billion Euro turnover in 2010. With a worldwide network of agencies and customer service companies, BSH currently includes 70 companies in 46 countries, employing over 43,000 people. BSH is the biggest household appliance manufacturer in Germany and Europe, and one of the industry leaders worldwide. Besides the main brands Bosch and Siemens, the BSH portfolio encompasses large and small household appliances, floor cleaning equipment and water heaters. Business management and development are driven by a clear strategic focus on quality and innovation. BSH offers well crafted products and the added value they bring to customers in terms of performance, comfort and ease of use. With this approach, the company promotes long-term customer satisfaction and trust in BSH brands.

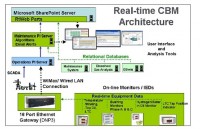

Every company is dependent on some type of asset that keeps the business in business – be it a computer, a centrifuge, or a megawatt transformer. In a large enterprise, reducing costs related to asset maintenance, repair, and ultimate replacement is at the top of management concerns. Downtime in any network, manufacturing, or computer system ultimately results not only in high repair costs, but in customer dissatisfaction and lower potential sales. In response to these concerns, this paper presents a methodology for creating a real-time Condition-based Maintenance (CBM) solution with the OSIsoft PI System. It provides valuable guidelines for planning an enterprise system that monitors critical maintenance processes and assets. This paper provides answers to many high priority CBM questions including:

Every company is dependent on some type of asset that keeps the business in business – be it a computer, a centrifuge, or a megawatt transformer. In a large enterprise, reducing costs related to asset maintenance, repair, and ultimate replacement is at the top of management concerns. Downtime in any network, manufacturing, or computer system ultimately results not only in high repair costs, but in customer dissatisfaction and lower potential sales. In response to these concerns, this paper presents a methodology for creating a real-time Condition-based Maintenance (CBM) solution with the OSIsoft PI System. It provides valuable guidelines for planning an enterprise system that monitors critical maintenance processes and assets. This paper provides answers to many high priority CBM questions including: It takes Pacesetters two steps to optimize their maintenance efforts. First they automate their realtime data acquisition and storage using standards-based software applications. Second, they implement CBM systems that assess equipment health based on timely and accurate information. This enables Pacesetters to prioritize their maintenance efforts by moving human and capital resources away from well functioning equipment to areas that scream for early attention.

It takes Pacesetters two steps to optimize their maintenance efforts. First they automate their realtime data acquisition and storage using standards-based software applications. Second, they implement CBM systems that assess equipment health based on timely and accurate information. This enables Pacesetters to prioritize their maintenance efforts by moving human and capital resources away from well functioning equipment to areas that scream for early attention. AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments.

AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments. Kepware Technologies, a software development company focused on communications for automation, announced today that leading power and automation company, ABB, has integrated KEPServerEX with its flagship product, 800xA Integrated Control and Safety System (ICSS). Selected as the main automation contractor for the world's first operation focused on converting gas from coal seams into liquefied natural gas, ABB utilizes Kepware's highly flexible and reliable communications platform to meet the project's demanding scalability needs.

Kepware Technologies, a software development company focused on communications for automation, announced today that leading power and automation company, ABB, has integrated KEPServerEX with its flagship product, 800xA Integrated Control and Safety System (ICSS). Selected as the main automation contractor for the world's first operation focused on converting gas from coal seams into liquefied natural gas, ABB utilizes Kepware's highly flexible and reliable communications platform to meet the project's demanding scalability needs.