AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments.

AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments.

AQUALGAE soon turned to InduSoft Web Studio to create flexible and robust SCADA/HMI systems that could grow with advancing technology in the increasingly important microalgae production industry.

With InduSoft Web Studio, AQUALGAE has been able to meet the shifting requirements of customers who require a robust and highly flexible SCADA/HMI system to control and monitor photobioreactor plants.

Microalgae are microscopic algae typically found in freshwater and marine systems. They have a very high photosynthetic efficiency and may be found in all habitats of our planet. Microalgae are the main primary producers and contribute to the major capture of CO2 from the atmosphere, with its concomitant O2 release. There is a tremendous biotechnology potential over microalgae still to be explored.

With climate change recognized as one of the top threats to our planet, microalgae may prove to be key for CO2 mitigation, creating biofuels, developing food and pharmaceuticals, and water/wastewater treatments. The vast array of products that can be produced through microalgae cultivation include everything from industrial applications to health and food supplements.

AQUALGAE is a company specialized in integral solutions for microalgae production, from small-scale labs to pilot-scale and large scale projects. The company designs, manufactures, and installs different type of photobioreactors, as well as offering microalgae starter cultures, culture media, and auxiliary equipment.

Due to the rapid growth in the industry, scalability is critical to new systems developed by AQUALGAE. When they discovered that their original SCADA software platform was not flexible enough to handle the growing demands of customers. AQUALGAE soon turned to InduSoft Web Studio to create flexible and robust SCADA/HMI systems that could scale easily with advancing technology.

Download Full Case Study by InduSoft

Footwear

Whitepaper by Iconics: Today’s manufacturing and building operations are faced with the need to reduce cost and be more competitive with the fewest of resources. Connectivity to different infrastructures for data gathering and the need to analyze and visualize data in real time is ever more important in today’s economic environment. Recently, visualization systems have taken a giant step forward incorporating advanced hardware accelerated 3D graphics into standard off -the shelf commercial products.

Whitepaper by Iconics: Today’s manufacturing and building operations are faced with the need to reduce cost and be more competitive with the fewest of resources. Connectivity to different infrastructures for data gathering and the need to analyze and visualize data in real time is ever more important in today’s economic environment. Recently, visualization systems have taken a giant step forward incorporating advanced hardware accelerated 3D graphics into standard off -the shelf commercial products.

Kepware Technologies, a software development company acquired by PTC® (Nasdaq: PTC) in January 2016, today announced that Faurecia, one of the world’s largest automotive equipment suppliers, has implemented Kepware’s IoT Gateway for KEPServerEX® to improve parts traceability throughout the entire manufacturing process—satisfying the needs of customers and internal stakeholders.

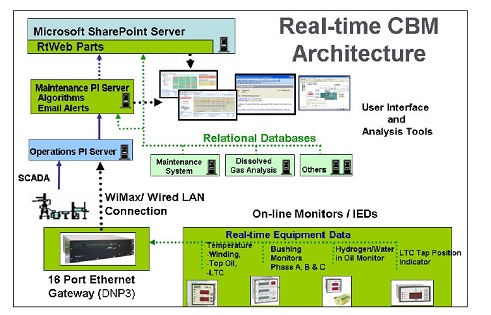

Kepware Technologies, a software development company acquired by PTC® (Nasdaq: PTC) in January 2016, today announced that Faurecia, one of the world’s largest automotive equipment suppliers, has implemented Kepware’s IoT Gateway for KEPServerEX® to improve parts traceability throughout the entire manufacturing process—satisfying the needs of customers and internal stakeholders. Every company is dependent on some type of asset that keeps the business in business – be it a computer, a centrifuge, or a megawatt transformer. In a large enterprise, reducing costs related to asset maintenance, repair, and ultimate replacement is at the top of management concerns. Downtime in any network, manufacturing, or computer system ultimately results not only in high repair costs, but in customer dissatisfaction and lower potential sales. In response to these concerns, this paper presents a methodology for creating a real-time Condition-based Maintenance (CBM) solution with the OSIsoft PI System. It provides valuable guidelines for planning an enterprise system that monitors critical maintenance processes and assets. This paper provides answers to many high priority CBM questions including:

Every company is dependent on some type of asset that keeps the business in business – be it a computer, a centrifuge, or a megawatt transformer. In a large enterprise, reducing costs related to asset maintenance, repair, and ultimate replacement is at the top of management concerns. Downtime in any network, manufacturing, or computer system ultimately results not only in high repair costs, but in customer dissatisfaction and lower potential sales. In response to these concerns, this paper presents a methodology for creating a real-time Condition-based Maintenance (CBM) solution with the OSIsoft PI System. It provides valuable guidelines for planning an enterprise system that monitors critical maintenance processes and assets. This paper provides answers to many high priority CBM questions including: “The elimination of manual operations for the measurement of OEE parameters has resulted into significant cycle time reduction. Based on the results achieved with this solution, we are considering its extension to other countries outside Europe.”

“The elimination of manual operations for the measurement of OEE parameters has resulted into significant cycle time reduction. Based on the results achieved with this solution, we are considering its extension to other countries outside Europe.”  AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments.

AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments.