The Yokogawa DTSX200 distributed temperature sensor (DTS) is used to monitor temperature, leaks, and flow in oil/gas downhole, pipeline, LNG/refinery tank/reactor vessel, fire detection, and other industrial thermal applications. Released in October 2011, the DTSX200 is the distributed temperature sensor with a STARDOM field controller option to improve production efficiency by working together with production control systems. The DTSX200 is being field tested for oil/gas in-well applications by some major oil companies. The DTSX200 is also being proposed for pipeline and tank leak detection systems.

The Yokogawa DTSX200 distributed temperature sensor (DTS) is used to monitor temperature, leaks, and flow in oil/gas downhole, pipeline, LNG/refinery tank/reactor vessel, fire detection, and other industrial thermal applications. Released in October 2011, the DTSX200 is the distributed temperature sensor with a STARDOM field controller option to improve production efficiency by working together with production control systems. The DTSX200 is being field tested for oil/gas in-well applications by some major oil companies. The DTSX200 is also being proposed for pipeline and tank leak detection systems.

For further details please click 'Distributed Temperature Sensor - DTSX200'

Nike Air VaporMax

Omron introduces Switch Mode Power Supply S8EX. New S8EX Series of Switch-mode Power Supply Boards:

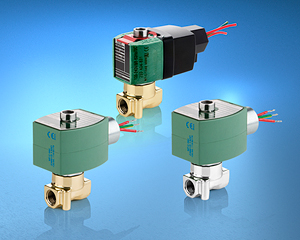

Omron introduces Switch Mode Power Supply S8EX. New S8EX Series of Switch-mode Power Supply Boards: 8314 Series Three-Way Direct Acting General Service Valves to Include Larger Orifice Sizes and the Electronically Enhanced Solenoid Valve Series Expands its Product Offering

8314 Series Three-Way Direct Acting General Service Valves to Include Larger Orifice Sizes and the Electronically Enhanced Solenoid Valve Series Expands its Product Offering Quebec, Canada, February 1, 2012 – ABB, the leading power and automation technology group, announces the introduction of the new MB-Rx in-situ Reaction Monitor for research laboratories and pilot plants in the chemical, petrochemical, pharmaceutical and biopharmaceutical industries.

Quebec, Canada, February 1, 2012 – ABB, the leading power and automation technology group, announces the introduction of the new MB-Rx in-situ Reaction Monitor for research laboratories and pilot plants in the chemical, petrochemical, pharmaceutical and biopharmaceutical industries.