The UC-8410A Series embedded computers support a rich collection of communication interfaces, including 8 RS-232/422/485 serial ports, 3 Ethernet ports, 1 PCIe mini slot for a wireless module, 4 digital input channels, 4 digital output channels, 1 mSATA slot, and 2 USB 2.0 hosts.

The UC-8410A Series embedded computers support a rich collection of communication interfaces, including 8 RS-232/422/485 serial ports, 3 Ethernet ports, 1 PCIe mini slot for a wireless module, 4 digital input channels, 4 digital output channels, 1 mSATA slot, and 2 USB 2.0 hosts.

The UC-8410A computer uses the Freescale Cortex-A7 dual-core 1 GHz RISC CPU. This powerful computing engine supports several useful communications functions, without generating too much heat. The built-in 1 GB SD card and 512 MB DDR3 SDRAM give you enough memory to run your application software, and the mSATA slot provides the flexibility of adding additional data storage. The UC-8410A comes with a variety of communication interaces, including serial ports, Ethernet ports, wireless communication slot, and digital input/output channels, making them ideal as communication platforms for industrial applications that require network and device communications.

The UC-8410A Series comes with Linux Debian 8 pre-installed to provide an open software operating system for software program development. This makes the UC-8410A computer an optimal solution for use with industrial applications, but at minimal cost and effort. In addition to the standard model, a -40 to 75°C wide temperature model is also available for harsh industrial environments.

Features and Benefits:

- Freescale LS1021A Coretex-A7 1 GHz dual-core processor

- 512 MB DDR3 SDRAM

- 8 RS-232/422/485 serial ports

- 3 10/100/1000 Mbps Ethernet ports

- Wireless-enabled with PCIe mini slot

- 2 USB 2.0 hosts for mass storage devices

- DIN-rail or wall-mounting installation

- Robust, fanless design

- -40 to 75°C wide temperature model available

- Ready-to-run Debian ARM 8

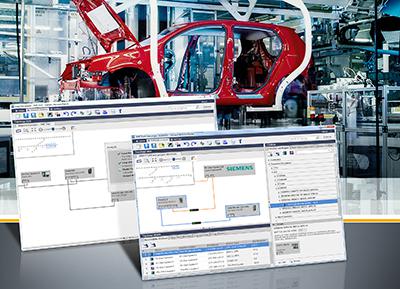

Siemens is launching a new software tool on the market for the design and simulation of Profinet automation networks. The Sinetplan network planner from Siemens is aimed at plant designers, constructors and operators and supports them from the planning stage, through commissioning to the operation of a Profinet communication network. In order to ensure subsequent operational reliability and to avoid problems during commissioning, the network is already designed with a suitable topological structure at the planning stage and any possible bottlenecks caused by peak loads, for example, are simulated. In the operating phase, Sinetplan offers transparency about the network capacity up to the port level of the individual stations by means of online scans, traffic shapers or reporting functions. This prevents unnecessary downtimes due to network overload and thus increases the availability of the network and the production.

Siemens is launching a new software tool on the market for the design and simulation of Profinet automation networks. The Sinetplan network planner from Siemens is aimed at plant designers, constructors and operators and supports them from the planning stage, through commissioning to the operation of a Profinet communication network. In order to ensure subsequent operational reliability and to avoid problems during commissioning, the network is already designed with a suitable topological structure at the planning stage and any possible bottlenecks caused by peak loads, for example, are simulated. In the operating phase, Sinetplan offers transparency about the network capacity up to the port level of the individual stations by means of online scans, traffic shapers or reporting functions. This prevents unnecessary downtimes due to network overload and thus increases the availability of the network and the production.

Siemens is currently launching Scalance XC-100, a new line of compact switches. Users can establish electrical and optical line and star structures for machine-level networking in the Simatic environment. The switches are characterized by their high number of ports and interfaces, a rugged housing, an extended temperature range of -40 to +70° C as well as approval for hazardous areas (ATEX Zone 2, IECEx). This makes them suitable for deployment in a wide range of environments where conditions may sometimes be harsh, such as in series machine construction, shipbuilding, transportation, and in the oil and gas industry. For example, users can integrate communication modules of a series machine with a data rate of up to 100 Mbit/s into a production network.

Siemens is currently launching Scalance XC-100, a new line of compact switches. Users can establish electrical and optical line and star structures for machine-level networking in the Simatic environment. The switches are characterized by their high number of ports and interfaces, a rugged housing, an extended temperature range of -40 to +70° C as well as approval for hazardous areas (ATEX Zone 2, IECEx). This makes them suitable for deployment in a wide range of environments where conditions may sometimes be harsh, such as in series machine construction, shipbuilding, transportation, and in the oil and gas industry. For example, users can integrate communication modules of a series machine with a data rate of up to 100 Mbit/s into a production network. The ioLogik 2500 is a smart remote I/O product with unique hardware and software designs, making it an ideal solution for a variety of industrial data acquisition applications. The ioLogik 2500’s hardware design includes a 4-port unmanaged Ethernet switch and 2 serial ports, enabling the ioLogik 2500 to seamlessly connect to a variety of field devices. One of the Ethernet ports can be used to link to 8 daisy-chained ioLogik E1200 expansion modules to provide more than 100 channels. The ioLogik 2500 acts as the “head” unit, with Click&Go Plus logic used to control the entire I/O array. Most importantly, the ioLogik 2500’s single IP is all that’s required to connect the entire I/O array to your network, providing the perfect solution for industrial field sites that have an insufficient number of IP addresses.

The ioLogik 2500 is a smart remote I/O product with unique hardware and software designs, making it an ideal solution for a variety of industrial data acquisition applications. The ioLogik 2500’s hardware design includes a 4-port unmanaged Ethernet switch and 2 serial ports, enabling the ioLogik 2500 to seamlessly connect to a variety of field devices. One of the Ethernet ports can be used to link to 8 daisy-chained ioLogik E1200 expansion modules to provide more than 100 channels. The ioLogik 2500 acts as the “head” unit, with Click&Go Plus logic used to control the entire I/O array. Most importantly, the ioLogik 2500’s single IP is all that’s required to connect the entire I/O array to your network, providing the perfect solution for industrial field sites that have an insufficient number of IP addresses.