CAS DataLoggers and Jager are proud to introduce a new processor board for ADwin-Pro-II Data Acquisition and Control Systems which has a 64-bit FPU (Floating-Point Unit) for math co-processing. The new Pro-CPU-T12 processor module offers powerful real-time computing and is largely software-compatible to previous versions. With Ethernet support enabling high-speed data transfer, ADwin’s Pro-CPU-T12 module enables standalone data recording in applications where there’s no PC or connection to one. This powerful solution is ideal for satisfying the most demanding applications including physics experiments, vibration monitoring, failure analysis, and high-speed data acquisition.

CAS DataLoggers and Jager are proud to introduce a new processor board for ADwin-Pro-II Data Acquisition and Control Systems which has a 64-bit FPU (Floating-Point Unit) for math co-processing. The new Pro-CPU-T12 processor module offers powerful real-time computing and is largely software-compatible to previous versions. With Ethernet support enabling high-speed data transfer, ADwin’s Pro-CPU-T12 module enables standalone data recording in applications where there’s no PC or connection to one. This powerful solution is ideal for satisfying the most demanding applications including physics experiments, vibration monitoring, failure analysis, and high-speed data acquisition.

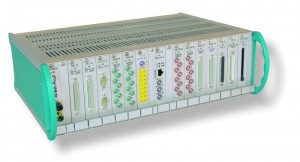

The Heart of the ADwin-Pro II System

The processor module--the ADwin CPU--is the center of each ADwin-Pro II data acquisition system. It executes the ADbasic programming instructions and accesses the inputs, outputs and interfaces of the other modules.

ADwin’s new Pro-CPU-T12 processor offers powerful Giga-performance, with a 1 Gigahertz clock, 1-Gigabyte main memory for storing code and data, and a 1-Gigabit Ethernet interface for communication to the PC. All this makes the 64-Bit double-precision FPU 5x faster than its predecessor module the CPU-T11. The T12 module also has a trigger input and 2 Digital I/Os, and as a special feature the board can also run C code embedded into ADbasic code. The module also enables stand-alone operation without a PC using the Bootloader.

Flexible Access:

Users have the choice of either USB or a SATA storage device on the module: the SATA device can either be integrated into the module or removable. Access to the memory is provided via processor module or via NFS/SMB/FTP from the Ethernet network.

ADwin data acquisition systems feature tightly-coupled analog and digital inputs along with counters to provide users’ applications with extremely low-latency operation. The ADwin-Pro II Series utilizes a modular form factor with plug-in modules to allow up to 480 analog or digital inputs in a single chassis, along with a high-performance 300 MHz DSP processor and Ethernet communications interface. Users also have a variety of other I/O options including CANbus, SSI, Profibus/Fieldbus, RS-232/485, and signal conditioner modules.

The extraordinary speed of the Pro-II system provides complex applications with a high data rate while the fast processor allows an intelligent pre-selection of relevant data, mathematical functions or digital channel filtering.

Nike

NI (Nasdaq: NATI), the provider of solutions that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced the NI SOM. It combines the Xilinx Zynq All Programmable system on a chip (SoC) with supporting components such as memory on a small PCB and features a complete middleware solution and ready-to-go Linux-based real-time operating system (RTOS) already integrated. The NI SOM gives design teams the customizability of a SOM without the increased time and risk of developing custom software.

NI (Nasdaq: NATI), the provider of solutions that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced the NI SOM. It combines the Xilinx Zynq All Programmable system on a chip (SoC) with supporting components such as memory on a small PCB and features a complete middleware solution and ready-to-go Linux-based real-time operating system (RTOS) already integrated. The NI SOM gives design teams the customizability of a SOM without the increased time and risk of developing custom software. Honeywell Resins and Chemicals has introduced a new Aegis® nylon resin designed to protect cables and electrical wiring used in industrial and consumer products.

Honeywell Resins and Chemicals has introduced a new Aegis® nylon resin designed to protect cables and electrical wiring used in industrial and consumer products. Siemens has launched two particularly slim, powerful and energy-efficient power supply units in the shape of the new Sitop PSU8200 5 A and 10 A. The single-phase power supplies, featuring 5 A or 10 A of rated output current respectively, expand the "Sitop modular" product range for high-end 24 V DC applications. Thanks to the wide input voltage ranges from 85 V to 132 V AC, and 170 V to 264 V AC, they can be connected to power systems worldwide. The power supply units are characterized by a slim design (45 mm for the 5 A version and 55 mm for the 10 A version), high efficiency of up to 94 percent, and high overload capability. They are therefore especially suitable for industrial environments with exacting reliability and functionality requirements, such as in car production, or in special-purpose machine manufacturing. They can be used in a temperature range of -25 to +70 degrees Celsius.

Siemens has launched two particularly slim, powerful and energy-efficient power supply units in the shape of the new Sitop PSU8200 5 A and 10 A. The single-phase power supplies, featuring 5 A or 10 A of rated output current respectively, expand the "Sitop modular" product range for high-end 24 V DC applications. Thanks to the wide input voltage ranges from 85 V to 132 V AC, and 170 V to 264 V AC, they can be connected to power systems worldwide. The power supply units are characterized by a slim design (45 mm for the 5 A version and 55 mm for the 10 A version), high efficiency of up to 94 percent, and high overload capability. They are therefore especially suitable for industrial environments with exacting reliability and functionality requirements, such as in car production, or in special-purpose machine manufacturing. They can be used in a temperature range of -25 to +70 degrees Celsius. The Firechek® FC-4 Series valve is a FM Approved heat activated pneumatic shut-off valve. When the FireChek senses excessive heat from a nearby fire, it immediately vents the pneumatic actuator and closes the actuator air supply line. FireChek triggers quickly, securing pneumatically operated process line valves. Because this valve responds to heat, not flame, it offers dramatically improved protection compared with conventional plastic tubing burn-through. It shuts off the air supply line to prevent plant air from feeding oxygen to a fire.

The Firechek® FC-4 Series valve is a FM Approved heat activated pneumatic shut-off valve. When the FireChek senses excessive heat from a nearby fire, it immediately vents the pneumatic actuator and closes the actuator air supply line. FireChek triggers quickly, securing pneumatically operated process line valves. Because this valve responds to heat, not flame, it offers dramatically improved protection compared with conventional plastic tubing burn-through. It shuts off the air supply line to prevent plant air from feeding oxygen to a fire.