Yokogawa Electric Corporation and Xybion Technology Solutions announce their collaboration on a white paper that shows how Yokogawa’s CENTUM® VP R5.03 integrated production control system can help users comply with the U.S. Food and Drug Administration’s (FDA) 21 CFR Part 11 regulations on electronic records and electronic signatures. This is the latest in a series of white papers that Yokogawa and Xybion have drawn up on new CENTUM releases and a variety of other Yokogawa products and platforms, and it is being jointly released by the two companies on this date.

Yokogawa Electric Corporation and Xybion Technology Solutions announce their collaboration on a white paper that shows how Yokogawa’s CENTUM® VP R5.03 integrated production control system can help users comply with the U.S. Food and Drug Administration’s (FDA) 21 CFR Part 11 regulations on electronic records and electronic signatures. This is the latest in a series of white papers that Yokogawa and Xybion have drawn up on new CENTUM releases and a variety of other Yokogawa products and platforms, and it is being jointly released by the two companies on this date.

In the food and pharmaceutical industries, meticulous change control is required. The production control systems that are used in these industries must provide records identifying the personnel who carry out each operation, and when that operation was performed. To ensure that the U.S. pharmaceutical industry observes proper change control, the FDA issued the 21 CFR Part 11 regulations in 1997. This regulatory statute stipulated the requirements under which the use of electronic records and signatures could have the same standing as conventional paper records and handwritten signatures. Starting with CENTUM CS 3000 R3 and continuing on through to the latest version (R5.03) of CENTUM VP, Yokogawa has incorporated features and functions in its integrated production control systems that help users comply with these regulations.

Other regulations impose similar requirements. These include Annex 11 of the good manufacturing practice (GMP*1) regulations that were formulated by the European Union’s European Medicines Agency (EMA), and the Japan Ministry of Health, Labour and Welfare’s (MHLW) ER/ES guidelines on the use of electromagnetic records and electronic signatures in applications for the approval/licensing of medical products. This facilitation of compliance with the FDA’s 21 CFR Part 11 regulations allows Yokogawa to offer its production control systems for food and pharmaceutical applications in these other regions. This is expected to also foster compliance with the Pharmaceutical Inspection Convention and Pharmaceutical Inspection Co-operation Scheme (PIC/S)*2. Yokogawa’s provision of tools that help users comply with 21 CFR Part 11 will accelerate the expansion of its industrial automation and control business in the growing medical market worldwide.

Nike Hyperdunk 2017

In response to marketplace demand and input from automation professionals, the International Society of Automation (ISA) announces today it has developed a new Automation Engineering Survival Training course designed to meet the needs and requirements of system integrators.

In response to marketplace demand and input from automation professionals, the International Society of Automation (ISA) announces today it has developed a new Automation Engineering Survival Training course designed to meet the needs and requirements of system integrators. Yokogawa has announced the new CENTUM VP and how it was going to take VigilantPlant, our vision for the ideal plant in industrial automation, to the next level. It exceeds the capabilities of conventional production systems and will become the platform based on which we will provide our customers with solutions and services that maintain operational excellence over the entire plant lifecycle. Innovations are available with it.

Yokogawa has announced the new CENTUM VP and how it was going to take VigilantPlant, our vision for the ideal plant in industrial automation, to the next level. It exceeds the capabilities of conventional production systems and will become the platform based on which we will provide our customers with solutions and services that maintain operational excellence over the entire plant lifecycle. Innovations are available with it.

Yokogawa Electric Corporation announces that it will release an enhanced version of the FCN-RTU* low-power autonomous controller for the STARDOM™ network-based control system on February 26. This new version of the FCN-RTU has been developed to meet the requirements of our customers in the high-growth upstream oil & gas industries.

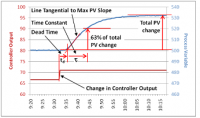

Yokogawa Electric Corporation announces that it will release an enhanced version of the FCN-RTU* low-power autonomous controller for the STARDOM™ network-based control system on February 26. This new version of the FCN-RTU has been developed to meet the requirements of our customers in the high-growth upstream oil & gas industries. Application Note by Data Forth: The well known Ziegler Nichols tuning rules work well only on processes with very long time constants relative to their dead times, and on level control loops. Its performance is not good on flow, liquid pressure, and many other loops. The Cohen-Coon tuning rules work well on virtually all self-regulating processes. These rules were originally designed to give a very fast response, but this results in loops with a very oscillatory response. With a slight modification of the Cohen-Coon tuning rules, control loops can still respond quickly, but they are much less prone to oscillations. This Application Note describes how to tune control loops using this modified Cohen-Coon tuning method.

Application Note by Data Forth: The well known Ziegler Nichols tuning rules work well only on processes with very long time constants relative to their dead times, and on level control loops. Its performance is not good on flow, liquid pressure, and many other loops. The Cohen-Coon tuning rules work well on virtually all self-regulating processes. These rules were originally designed to give a very fast response, but this results in loops with a very oscillatory response. With a slight modification of the Cohen-Coon tuning rules, control loops can still respond quickly, but they are much less prone to oscillations. This Application Note describes how to tune control loops using this modified Cohen-Coon tuning method.