Schneider Electric, a global specialist in energy management and automation, today released its Tricon® CX compact system for safety and critical control applications in the oil and gas, power, refining, chemicals, pharmaceutical and biotech industries, where safe operations are critical and reliable operation is paramount. A certified ISA Secure system, the high-integrity and highly available Tricon CX ensures operational integrity, protecting against inherent risk and hazards, as well as external threats such as cyber-attack.

Schneider Electric, a global specialist in energy management and automation, today released its Tricon® CX compact system for safety and critical control applications in the oil and gas, power, refining, chemicals, pharmaceutical and biotech industries, where safe operations are critical and reliable operation is paramount. A certified ISA Secure system, the high-integrity and highly available Tricon CX ensures operational integrity, protecting against inherent risk and hazards, as well as external threats such as cyber-attack.

“Safety and security have always been a top concern for our industrial clients, but now new threats, such as cyber-attack, have challenged the traditional approaches they have taken to protect and secure their people, property, communities and the environment,” said Mike Chmilewski, vice president, process systems offer management, Schneider Electric process automation business. “Therefore, our clients demand the highest levels of safety and security to keep them safe and ensure the systems they rely on are immune to external threats. Our high-performance, future-proof Tricon CX safety system does just that. With more performance and capability, it can help clients maximize productivity, reliability and security while minimizing risks and the likelihood of business interruption. It’s another example of why Schneider Electric is uniquely positioned to power the big ideas our clients need to solve their most critical issues.”

The latest addition to Schneider Electric’s Triconex® line of safety-instrumented systems, the Tricon CX is smaller, faster, lighter and more powerful than previous safety solutions. Its advanced functionality enables online upgrades without operational interruption. Additionally, the compact design allows for a number of new features including:

- Reduced form factor by 50 percent

- 67 percent reduction in weight

- Lower power consumption

- Advanced monitoring and control capabilities, including:

- Supervised DI/DO with advanced line-performance diagnostics

- Fast analogue inputs with integrated HART

- 1ms SOE digital input

- Choice of direct termination or external termination panel

- 300 percent increase in controller tag capacity

- 5 times increase in peer-to-peer performance

- ISA Secure EDSA level 1

- New automated test and verification of safety logic

“The Tricon CX safety system will enhance Schneider Electric’s current safety portfolio, and ARC believes its increased capabilities will enable new and existing customers to expand existing systems, replace obsolete systems or implement new systems,” said Larry O'Brien, vice president, process automation, ARC Advisory Group. “Its ability to handle upgrades without interrupting the operation should give users confidence in their ability to continue to draw additional value from their investments down the road.”

Through its Triconex brand, Schneider Electric offers industry-leading safety and critical control solutions for managing risks in hazardous environments. Triconex solutions enable safer operations by maximizing compliance to mandated safety regulations and minimizing both unscheduled downtime and the likelihood of business interruptions. The systems improve operational efficiency, helping clients achieve gains in production availability, asset uptime and ROI. Based on industry-leading Triple Modular Redundancy technology, Triconex solutions are also easy to operate and maintain, and they provide a higher total value of ownership over competitive offers.

In addition to leading technology and solution sets, Schneider Electric’s process safety offer includes more than 650 safety engineers who provide a suite of services that help clients better manage their operations. These services include:

- Safety Instrumented Functions Management services

- Process safety consulting services

- Functional safety learning services

Lebron XIV 14 Low

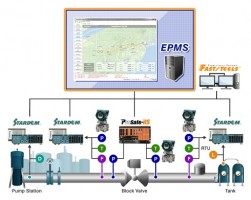

Yokogawa Electric Corporation announces the June 30 release of the Enterprise Pipeline Management Solution (EPMS), a modular software suite that is the product of our over 20 years of practical experience in implementing pipeline management solutions across the globe.

Yokogawa Electric Corporation announces the June 30 release of the Enterprise Pipeline Management Solution (EPMS), a modular software suite that is the product of our over 20 years of practical experience in implementing pipeline management solutions across the globe.

The new ADAM-3600 is an intelligent RTU designed to work in the hardest environments with minimal physical contact from engineers once installed. The ADAM-3600 utilizes Advantech’s TagLink Technology, a modular wireless expansion system and wide operating temperatures.

The new ADAM-3600 is an intelligent RTU designed to work in the hardest environments with minimal physical contact from engineers once installed. The ADAM-3600 utilizes Advantech’s TagLink Technology, a modular wireless expansion system and wide operating temperatures. Yokogawa Electric Corporation announces that it will release an enhanced version of the STARDOM™ network-based control system on June 3. The new STARDOM version features enhancements that reduce communication costs and ensure highly reliable monitoring and control. These enhancements meet a variety of needs in upstream oil and gas development and production, which Yokogawa is targeting based on its Transformation 2017 mid-term business plan.

Yokogawa Electric Corporation announces that it will release an enhanced version of the STARDOM™ network-based control system on June 3. The new STARDOM version features enhancements that reduce communication costs and ensure highly reliable monitoring and control. These enhancements meet a variety of needs in upstream oil and gas development and production, which Yokogawa is targeting based on its Transformation 2017 mid-term business plan. Yokogawa Electric Corporation announces that Yokogawa and Shell have jointly developed Platform for Advanced Control and Estimation, a software suite that speeds up and simplifies the process of designing, deploying, and maintaining advanced process control applications.

Yokogawa Electric Corporation announces that Yokogawa and Shell have jointly developed Platform for Advanced Control and Estimation, a software suite that speeds up and simplifies the process of designing, deploying, and maintaining advanced process control applications.