An Easy to understand and well written book in the field of Industry Instrumentation, can be downloaded here for Free. This book is written in the form of tutorials and teaching style for quick learning of basics of Instrumentation. This book can be read by all learners such as Engineers, Senior Engineers, Technicians and people having interest in this field. Consisting of 18 Chapters, 646 Pages and Starting from basics of Science and taking it towards Instrumentation, this Book is definitely a good reference.

An Easy to understand and well written book in the field of Industry Instrumentation, can be downloaded here for Free. This book is written in the form of tutorials and teaching style for quick learning of basics of Instrumentation. This book can be read by all learners such as Engineers, Senior Engineers, Technicians and people having interest in this field. Consisting of 18 Chapters, 646 Pages and Starting from basics of Science and taking it towards Instrumentation, this Book is definitely a good reference.

The major topics covered are:

- Physics

- Chemistry

- DC Electricity

- AC Electricity

- Introduction to Industrial Instrumentation

- Instrumentation Documents

- Discrete process Measurement

- Analog Electronic Instrumentation

- Pneumatic Instrumentation

- Digital Electronic Instrumentation

- Instrument Calibration

- Continuous Pressure Measurement

- Continuous Level Measurement

- Continuous Temperature Measurement

- Continuous Fluid Flow Measurement

- Continuous Analytical Measurement

- Signal Characterization

- Continuous Feedback Control

Register with this website and click here to Download your Free Book

Nike EPIC React Flyknit

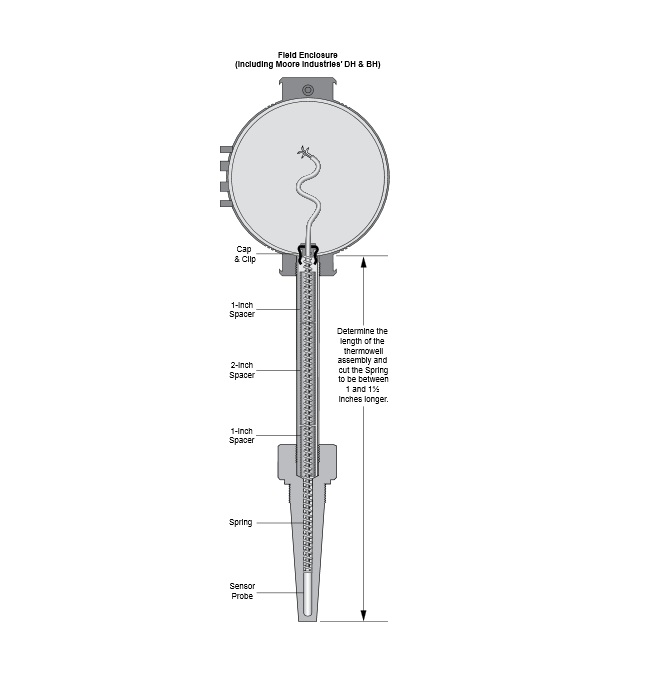

gth inherent to the 1000 ohm sensor available in Moore Industries products such as the WORM Flexible Temperature Sensor. This benefit can be seen in greater accuracy when used for smaller minimum measurement spans. Each point of measurement has 10 times more resistance along with a greater change in resistance per degree.

gth inherent to the 1000 ohm sensor available in Moore Industries products such as the WORM Flexible Temperature Sensor. This benefit can be seen in greater accuracy when used for smaller minimum measurement spans. Each point of measurement has 10 times more resistance along with a greater change in resistance per degree. Case Study by Emerson: Reliance Industries Ltd., ranked 99th on the Fortune 500 list of the world’s major corporations, operates the largest refinery and petrochemical complex. Located in Jamnagar, Gujarat, India, this refinery processes 1.24 million bpd (MMbpd) of crude oil. Largely due to this facility, Jamnagar has emerged as one of the world’s refining hubs. This refinery features the world’s largest crude distillation, fluid catalytic cracking, delayed coking and paraxylene (PX) units. The complex involves the operation of 50 various processing units to produce PX, ethylene, polyethylene, polypropylene, transportation fuels (diesel, gasoline and aviation fuels), and many other products.

Case Study by Emerson: Reliance Industries Ltd., ranked 99th on the Fortune 500 list of the world’s major corporations, operates the largest refinery and petrochemical complex. Located in Jamnagar, Gujarat, India, this refinery processes 1.24 million bpd (MMbpd) of crude oil. Largely due to this facility, Jamnagar has emerged as one of the world’s refining hubs. This refinery features the world’s largest crude distillation, fluid catalytic cracking, delayed coking and paraxylene (PX) units. The complex involves the operation of 50 various processing units to produce PX, ethylene, polyethylene, polypropylene, transportation fuels (diesel, gasoline and aviation fuels), and many other products. Moore Industries has published a new white paper on an application using the WORM Flexible Temperature Sensors to measure the temperature of molasses during the production of beet sugar. Using the WORM as a replacement for standard thermowells allows site engineers to get more accurate temperature readings and maximize the amount of sugar recovered from the molasses.

Moore Industries has published a new white paper on an application using the WORM Flexible Temperature Sensors to measure the temperature of molasses during the production of beet sugar. Using the WORM as a replacement for standard thermowells allows site engineers to get more accurate temperature readings and maximize the amount of sugar recovered from the molasses. Rotork’s innovative CVA electric control valve actuators are enabling the Sydney Water Corporation in Australia to control the pressure in the city’s water supply network with greatly increased response and accuracy.

Rotork’s innovative CVA electric control valve actuators are enabling the Sydney Water Corporation in Australia to control the pressure in the city’s water supply network with greatly increased response and accuracy.