Rotork Schischek ExMax explosionproof actuators have been selected to assist the production of biogas for district heating systems in the German city of Munich. Biogas is produced during the effluent treatment process at the city’s largest waste water plant Klaerwerk Gut Grosslappen, situated close to the world famous Munich Allianz Arena, home to Bayern Munich football club.

Rotork Schischek ExMax explosionproof actuators have been selected to assist the production of biogas for district heating systems in the German city of Munich. Biogas is produced during the effluent treatment process at the city’s largest waste water plant Klaerwerk Gut Grosslappen, situated close to the world famous Munich Allianz Arena, home to Bayern Munich football club.

The ExMax actuators have been installed in the digester and fermentation tanks, where all electrical equipment must be approved for use in hazardous areas. Built inside four large towers, the fermentation tanks mix the waste at a defined temperature to produce the biogas. For optimum performance the inner tank temperature must be maintained at 38ºC. Six ExMax actuators are installed in an area known as the lamp at the top of each tower for the operation of air dampers to balance the inside temperature with fluctuating ambient temperatures on the outside.

Factors favouring the Rotork Schischek products for this application include their compact size, ease of installation, standardised connections and Zone 1 hazardous area explosionproof certification. In addition Rotork Schischek has developed established relationships with the damper OEM, local engineering companies and the end user.

All Rotork Schischek products are manufactured with colour coding to indicate at a glance the appropriate hazardous or non-hazardous area of application. Yellow denotes hazardous Zones 1, 2, 21 and 22, red denotes hazardous Zones 2 and 22 and green denotes non-hazardous areas only

Men's Sneaker Hub Online

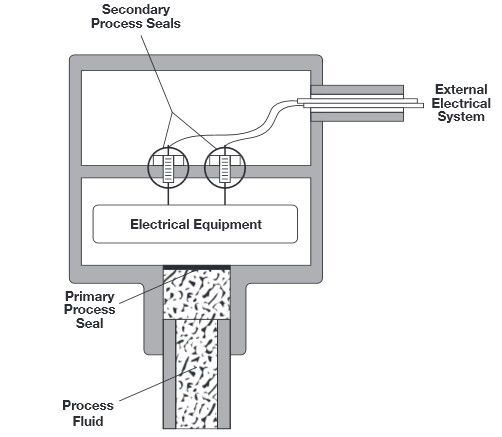

White Paper by Magnetrol: Over the years, well defined standards have been established to address the requirements for process sealing between electrical system and process fluids, where a failure could allow migration of fluid into the electrical system. The primary audience for this are the users of the process operators and facilities and installers of electrical system and instrumentation.

White Paper by Magnetrol: Over the years, well defined standards have been established to address the requirements for process sealing between electrical system and process fluids, where a failure could allow migration of fluid into the electrical system. The primary audience for this are the users of the process operators and facilities and installers of electrical system and instrumentation.

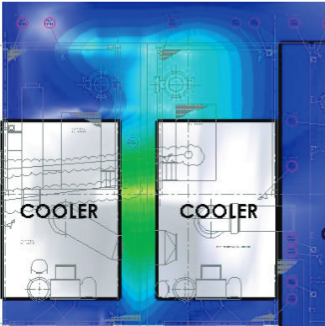

Case Study by Honeywell: Ultrasonic gas leak detection (UGLD) is capable of offering an enhanced mechanism for detecting pressurised gas leaks in applications where more traditional technologies fail to perform effectively due to high natural ventilation rates or excessive vibration. Detection methods such as point and open path IR absorption, catalytic beads and EC cells are dependent on large localised gas clouds forming in order to detect a gas leak. Such gas clouds form well in enclosed areas however, in exposed or elevated areas subject to strong winds leaking gas dilutes quickly with the leak potentially going undetected for long periods of time.

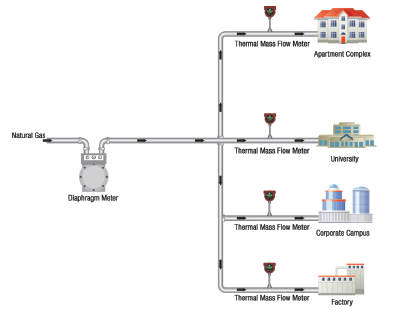

Case Study by Honeywell: Ultrasonic gas leak detection (UGLD) is capable of offering an enhanced mechanism for detecting pressurised gas leaks in applications where more traditional technologies fail to perform effectively due to high natural ventilation rates or excessive vibration. Detection methods such as point and open path IR absorption, catalytic beads and EC cells are dependent on large localised gas clouds forming in order to detect a gas leak. Such gas clouds form well in enclosed areas however, in exposed or elevated areas subject to strong winds leaking gas dilutes quickly with the leak potentially going undetected for long periods of time. Unlike oil, natural gas exists in abundance in the United States. Of the natural gas consumed in the United States in 2011, 95% was produced domestically. The U.S. Energy Information Administration projects U.S. natural gas production to increase from 23.0 trillion cubic feet in 2011 to 33.1 trillion cubic feet in 2040, a 44% increase. Almost all of this increase in domestic natural gas production is due to projected growth in shale gas production, which will grow from 7.8 trillion cubic feet in 2011 to 16.7 trillion cubic feet in 2040. This natural gas boon highlights the importance for utility companies to provide homes, businesses, and mid-to-large size facilities with accurate natural gas billing. Traditionally, utility companies have used diaphragm meters to measure natural gas usage, which is then charged to customers on their monthly energy bill. Although diaphragm meters are a trusted billing mechanism by utility companies, they may not provide customers with the most accurate natural gas bill. Diaphragm meters have limitations in natural gas measurement. If the diaphragm meter does not accurately measure the natural gas, this can result in utility companies overcharging customers.

Unlike oil, natural gas exists in abundance in the United States. Of the natural gas consumed in the United States in 2011, 95% was produced domestically. The U.S. Energy Information Administration projects U.S. natural gas production to increase from 23.0 trillion cubic feet in 2011 to 33.1 trillion cubic feet in 2040, a 44% increase. Almost all of this increase in domestic natural gas production is due to projected growth in shale gas production, which will grow from 7.8 trillion cubic feet in 2011 to 16.7 trillion cubic feet in 2040. This natural gas boon highlights the importance for utility companies to provide homes, businesses, and mid-to-large size facilities with accurate natural gas billing. Traditionally, utility companies have used diaphragm meters to measure natural gas usage, which is then charged to customers on their monthly energy bill. Although diaphragm meters are a trusted billing mechanism by utility companies, they may not provide customers with the most accurate natural gas bill. Diaphragm meters have limitations in natural gas measurement. If the diaphragm meter does not accurately measure the natural gas, this can result in utility companies overcharging customers. To optimize plant performance and prevent expensive turbine damage, rapid control is critical for industrial power markets covering multiple energy sources. Maintaining turbine efficiency is an even higher priority today because of lower emission requirements and varying fuel sources due to the increase in unconventional natural gas sources, such as shale. Plant gas sources are primarily composed of methane, but typically there are extensive variations in higher hydrocarbons (C2+) as well. In fact, in some cases, over 18 percent variation has been recorded with fluctuations from 10 percent to 16 percent within one minute. Turbines have to be more flexible and need to present the above criteria over a wide range of loads because gas turbine power plants are often used only for peak loads.

To optimize plant performance and prevent expensive turbine damage, rapid control is critical for industrial power markets covering multiple energy sources. Maintaining turbine efficiency is an even higher priority today because of lower emission requirements and varying fuel sources due to the increase in unconventional natural gas sources, such as shale. Plant gas sources are primarily composed of methane, but typically there are extensive variations in higher hydrocarbons (C2+) as well. In fact, in some cases, over 18 percent variation has been recorded with fluctuations from 10 percent to 16 percent within one minute. Turbines have to be more flexible and need to present the above criteria over a wide range of loads because gas turbine power plants are often used only for peak loads. Rotork Schischek ExMax explosionproof actuators have been selected to assist the production of biogas for district heating systems in the German city of Munich. Biogas is produced during the effluent treatment process at the city’s largest waste water plant Klaerwerk Gut Grosslappen, situated close to the world famous Munich Allianz Arena, home to Bayern Munich football club.

Rotork Schischek ExMax explosionproof actuators have been selected to assist the production of biogas for district heating systems in the German city of Munich. Biogas is produced during the effluent treatment process at the city’s largest waste water plant Klaerwerk Gut Grosslappen, situated close to the world famous Munich Allianz Arena, home to Bayern Munich football club.