Case Study: With milk and dairy production running 365 days a year, removal of measurement instruments for calibration posed a significant challenge for Al Safi Danone. Endress+Hauser’s customized and flexible calibration process ensured Al Safi Danone’s production could continue unhindered.

Case Study: With milk and dairy production running 365 days a year, removal of measurement instruments for calibration posed a significant challenge for Al Safi Danone. Endress+Hauser’s customized and flexible calibration process ensured Al Safi Danone’s production could continue unhindered.

- Al Safi Danone’s production equipment always available as required and functioning as specified

- Timely issuance of calibration certificates for food safety and CCP Audits.

The customer’s challenge: Al Safi Danone does not underestimate the importance of timely and accurate calibration of its production equipment to minimize waste and enhance the quality of output. Indeed, in an industry as demanding as Food & Beverage it is vital.

Download complete Case Study or read at Endress & Houser web.

White Paper by Honeywell highlights that there are significant hidden costs in most of the current practices for validating, verifying and documenting that Safety Instrumented Systems and control systems as installed are functioning as designed. One key reason is that until now, there has been no automated mechanisms to support this critical activity. There are no standard ways in the industry to achieve this validation, verification and documentation.

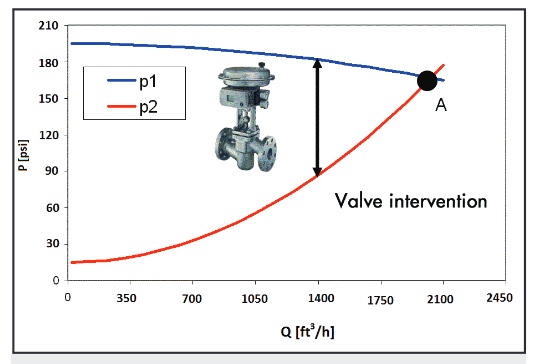

White Paper by Honeywell highlights that there are significant hidden costs in most of the current practices for validating, verifying and documenting that Safety Instrumented Systems and control systems as installed are functioning as designed. One key reason is that until now, there has been no automated mechanisms to support this critical activity. There are no standard ways in the industry to achieve this validation, verification and documentation. Article by Samson Valves: The discussions revolving around the scarcity of fossil fuels and increasing energy prices have refocused on the most effective action in the long term, i.e., reducing energy consumption. The right process automation technology can contribute to achieving considerable energy savings. Status monitoring and status conservation can be of help when optimizing the technical infrastructure by preventing additional energy consumption due to plant failures, the resulting start-up and shutdown procedures, as well as the production of non-conforming products. Three major areas can also be identified when optimizing the production process—process sizing, process monitoring, and process control. This article deals with the control valve as a final control element that can help minimize energy consumption when it is accurately tuned to its assigned task. In addition, we will look at state-of-the-art asset management concepts based on smart positioners, which facilitate energy monitoring and indicate possible savings potential thanks to optimized operating modes.

Article by Samson Valves: The discussions revolving around the scarcity of fossil fuels and increasing energy prices have refocused on the most effective action in the long term, i.e., reducing energy consumption. The right process automation technology can contribute to achieving considerable energy savings. Status monitoring and status conservation can be of help when optimizing the technical infrastructure by preventing additional energy consumption due to plant failures, the resulting start-up and shutdown procedures, as well as the production of non-conforming products. Three major areas can also be identified when optimizing the production process—process sizing, process monitoring, and process control. This article deals with the control valve as a final control element that can help minimize energy consumption when it is accurately tuned to its assigned task. In addition, we will look at state-of-the-art asset management concepts based on smart positioners, which facilitate energy monitoring and indicate possible savings potential thanks to optimized operating modes. Utilizing and maintaining level and flow control instrumentation requires knowledge of a wide range of technical information. Having a quick and comprehensive reference point for this information can help keep equipment running smoothly and efficiently. With that in mind, Magnetrol® has produced a free field instrumentation technical handbook featuring a compendium of physical constants, tables and other essential information. The handbook was created by MAGNETROL to cover specific reference points that are commonly used in process applications.

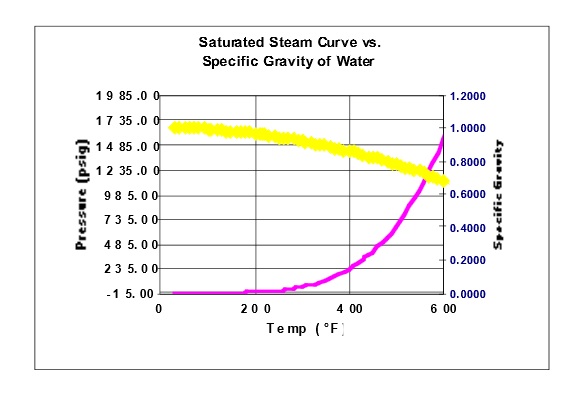

Utilizing and maintaining level and flow control instrumentation requires knowledge of a wide range of technical information. Having a quick and comprehensive reference point for this information can help keep equipment running smoothly and efficiently. With that in mind, Magnetrol® has produced a free field instrumentation technical handbook featuring a compendium of physical constants, tables and other essential information. The handbook was created by MAGNETROL to cover specific reference points that are commonly used in process applications. The accurate measurement of liquid levels in power plant operations is key to efficient operation. Although water is a liquid that can be easily measured by numerous measurement technologies, detection in applications like feedwater heaters, for example, takes on a range of complexity that stresses even the most robust devices.

The accurate measurement of liquid levels in power plant operations is key to efficient operation. Although water is a liquid that can be easily measured by numerous measurement technologies, detection in applications like feedwater heaters, for example, takes on a range of complexity that stresses even the most robust devices.