The new Remote Hand Station enables safe and secure local monitoring and control of Rotork IQ3 actuators installed in inaccessible locations. Rotork’s superior solution provides the user with an exact duplicate of the actuator’s own monitoring and control interface, at a distance of up to 100 metres from the valve. Power for the Remote Hand Station is supplied by the actuator, with which the unit shares all the benefits of the same IP68 double O-ring sealed environmental enclosure. There is no need for expensive cabling; standard comms wiring suitable for the operating environment is all that is required between the actuator and the Remote Hand Station.

The new Remote Hand Station enables safe and secure local monitoring and control of Rotork IQ3 actuators installed in inaccessible locations. Rotork’s superior solution provides the user with an exact duplicate of the actuator’s own monitoring and control interface, at a distance of up to 100 metres from the valve. Power for the Remote Hand Station is supplied by the actuator, with which the unit shares all the benefits of the same IP68 double O-ring sealed environmental enclosure. There is no need for expensive cabling; standard comms wiring suitable for the operating environment is all that is required between the actuator and the Remote Hand Station.

The user can remotely operate, interrogate and configure the actuator using the Rotork hand-held setting tool with its secure wireless Bluetooth link. Retaining all of the actuator’s functionality, the Remote Hand Station presents an identical window into the process, showing diagnostic data including the valve torque and usage profiles along with service logs and facilitating real time analysis directly at the unit.

Alternatively, information from the actuator datalogger can be downloaded and transferred to a PC for analysis using Rotork Insight2 diagnostic software to enable valve maintenance requirements to be identified and anticipated.

Designed for wall or pole mounted installation, the Remote Hand Station is available with explosionproof certification and can also be equipped with a vandal proof cover to prevent unauthorised interference.

Nike Hypervenom Phantom II FG Low

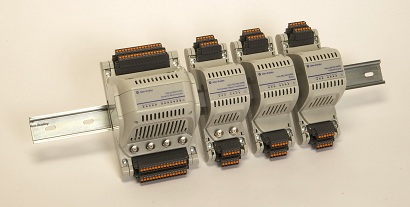

Manufacturers can monitor and protect machinery at a lower total cost of ownership with the Allen-Bradley Dynamix 1444 Series monitors from Rockwell Automation. The new integrated condition-monitoring system allows manufacturers to leverage the Rockwell Automation Integrated Architecture system, rather than an isolated condition-monitoring device, to assess current equipment health, predict potential issues, and help avoid damage to critical machinery. Integration of machinery health into control architectures using a standard Ethernet TCP/IP EtherNet/IP network brings unprecedented flexibility to machine instrumentation design and operational efficiency on the manufacturing floor.

Manufacturers can monitor and protect machinery at a lower total cost of ownership with the Allen-Bradley Dynamix 1444 Series monitors from Rockwell Automation. The new integrated condition-monitoring system allows manufacturers to leverage the Rockwell Automation Integrated Architecture system, rather than an isolated condition-monitoring device, to assess current equipment health, predict potential issues, and help avoid damage to critical machinery. Integration of machinery health into control architectures using a standard Ethernet TCP/IP EtherNet/IP network brings unprecedented flexibility to machine instrumentation design and operational efficiency on the manufacturing floor. Saelig Company Inc. has introduced the Lascar EL-ENVIROPAD-TC - a conveniently-sized thermocouple-based temperature meter for spot temperature readings with additional built-in data-logging and graphing functionalities. This robust and easy to use handheld device takes and records temperature readings via the supplied K-type thermocouple probe. Control and display is via a 2.8" color touch screen, which indicates current temperature to a resolution of 0.1degC, maximum and minimum readings, and will produce an immediate graph of the data readings. Operation is user-selectable in Fahrenheit or Centigrade.

Saelig Company Inc. has introduced the Lascar EL-ENVIROPAD-TC - a conveniently-sized thermocouple-based temperature meter for spot temperature readings with additional built-in data-logging and graphing functionalities. This robust and easy to use handheld device takes and records temperature readings via the supplied K-type thermocouple probe. Control and display is via a 2.8" color touch screen, which indicates current temperature to a resolution of 0.1degC, maximum and minimum readings, and will produce an immediate graph of the data readings. Operation is user-selectable in Fahrenheit or Centigrade. The condition of the bearings in your industrial equipment is tied to the condition of your machinery and your process itself. Equipment operating at high temperatures or at low speed is prone to premature bearing or gear failure, which can cause a process shutdown costing many hours of lost production. Now CAS DataLoggers can supply your business with wired and wireless temperature monitoring systems for reliable condition monitoring and alarming of bearings in process-critical equipment including compressor motors, turbines and conveyors.

The condition of the bearings in your industrial equipment is tied to the condition of your machinery and your process itself. Equipment operating at high temperatures or at low speed is prone to premature bearing or gear failure, which can cause a process shutdown costing many hours of lost production. Now CAS DataLoggers can supply your business with wired and wireless temperature monitoring systems for reliable condition monitoring and alarming of bearings in process-critical equipment including compressor motors, turbines and conveyors. The KOBOLD VKG series viscosity-compensating flowmeters and flow switches fill an important gap in the high viscosity media measurement field. Using KOBOLD’s patented viscosity-compensation system, these flowmeters and flow switches are largely insensitive to viscosity and density changes during operation. This development in flow and measurement control technology has resulted in an extremely versatile viscosity-compensated flowmeter and flow switch usable in many viscous-media applications.

The KOBOLD VKG series viscosity-compensating flowmeters and flow switches fill an important gap in the high viscosity media measurement field. Using KOBOLD’s patented viscosity-compensation system, these flowmeters and flow switches are largely insensitive to viscosity and density changes during operation. This development in flow and measurement control technology has resulted in an extremely versatile viscosity-compensated flowmeter and flow switch usable in many viscous-media applications.