Cobham Wireless, formerly the Wireless Test Business of Aeroflex, and NI (Nasdaq: NATI), the provider of platform-based systems that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced a worldwide partnership to service applications in cellular and connectivity with solutions based on PXI technology.

Cobham Wireless, formerly the Wireless Test Business of Aeroflex, and NI (Nasdaq: NATI), the provider of platform-based systems that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced a worldwide partnership to service applications in cellular and connectivity with solutions based on PXI technology.

Under the terms of the agreement, NI acquires the existing Cobham PXI modular instruments hardware product line and becomes Cobham’s primary provider of PXI technology. The acquired PXI modular instruments will be manufactured by NI and supplied exclusively to Cobham for sale through the Cobham Wireless business unit’s direct sales channels and brand, which will ensure continuity and continued support for existing PXI-based customers. The companies will also collaborate to incorporate the latest NI PXI modular instruments, including the NI vector signal transceiver with LabVIEW FPGA, into Cobham’s next-generation cellular and connectivity test systems.

With the agreement, Cobham Wireless will become the NI Global Preferred Partner for Cellular and Connectivity Applications, part of the NI Alliance Partner Network.

“We are excited to partner with Cobham,” said Pete Zogas, senior vice president of Segments and Services at NI. “As wireless industry leaders, they have the resources necessary to provide solutions and services on a global scale. Our customers will benefit greatly from the combination of the NI platform and Cobham’s unique domain-specific expertise within the cellular and connectivity application space.”

Ian Langley, senior vice president and general manager of the Cobham Wireless Business Unit, said, “With increased test complexity and faster design cycles, we chose to build our RF and wireless test systems based on NI’s industry-leading PXI modular instrumentation technology. The combination of LabVIEW FPGA and the NI vector signal transceiver enables us to deliver products and solutions to our customers with optimum performance and the lowest cost of test.”

Companies testing the cellular and connectivity capabilities of their products are increasingly transitioning to a software-defined modular approach using PXI to lower test costs, shorten test times and provide flexibility to adapt to changing test requirements. Because of the partnership between Cobham and NI, customers will benefit from the expertise, reputation and support of Cobham in cellular and connectivity test applications with systems based on modular instrumentation from NI, the world leader in PXI.

JUNIOR

The launch of the Rotork CQ Compact introduces a range of fully concentric, balanced design pneumatic and hydraulic valve actuators that deliver a reliable and efficient self-contained solution for applications demanding functional integrity and safety where space is limited.

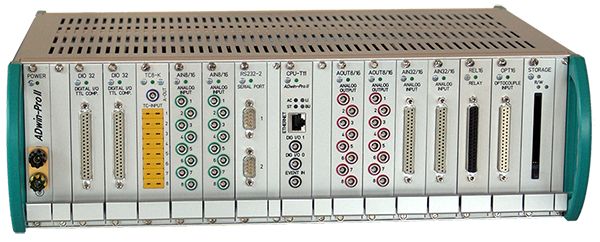

The launch of the Rotork CQ Compact introduces a range of fully concentric, balanced design pneumatic and hydraulic valve actuators that deliver a reliable and efficient self-contained solution for applications demanding functional integrity and safety where space is limited. CAS DataLoggers in partnership with Jager-ADwin is pleased to announce the new T-12 processor module for ADwin-PRO II data acquisition and control systems. Featuring powerful ARM-based processor technology, the new ADwin CPU enables superior performance at real-time speed.

CAS DataLoggers in partnership with Jager-ADwin is pleased to announce the new T-12 processor module for ADwin-PRO II data acquisition and control systems. Featuring powerful ARM-based processor technology, the new ADwin CPU enables superior performance at real-time speed. Rotork Midland introduces SMART-LOC, a new high integrity modular concept for pneumatic actuator control assemblies. Constructed in 316L stainless steel, the SMART-LOC system is particularly suitable for the control and sequencing of process valve actuators in oil and gas applications.

Rotork Midland introduces SMART-LOC, a new high integrity modular concept for pneumatic actuator control assemblies. Constructed in 316L stainless steel, the SMART-LOC system is particularly suitable for the control and sequencing of process valve actuators in oil and gas applications. The Rotork Skilmatic SI self-contained electro-hydraulic valve actuator combines all-electric simplicity with the precision of hydraulic actuation and the reliability of mechanical failsafe operation. Typical applications for Skilmatic actuators include functional safety related Emergency Shutdown (ESD) and Remotely Operated Shutoff Valve (ROSoV) duties.

The Rotork Skilmatic SI self-contained electro-hydraulic valve actuator combines all-electric simplicity with the precision of hydraulic actuation and the reliability of mechanical failsafe operation. Typical applications for Skilmatic actuators include functional safety related Emergency Shutdown (ESD) and Remotely Operated Shutoff Valve (ROSoV) duties.