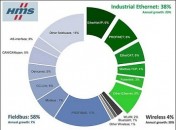

Industrial Ethernet is growing faster than before and now accounts for 38% of the market. EtherNet/IP is in first place within industrial Ethernet globally, followed by PROFINET. However, classic fieldbuses are still dominating the fragmented world of industrial networks with 58% and PROFIBUS is still the most widely used industrial network. Furthermore, the Internet of Things is driving wireless technologies which are now on the chart for the first time.

Industrial Ethernet is growing faster than before and now accounts for 38% of the market. EtherNet/IP is in first place within industrial Ethernet globally, followed by PROFINET. However, classic fieldbuses are still dominating the fragmented world of industrial networks with 58% and PROFIBUS is still the most widely used industrial network. Furthermore, the Internet of Things is driving wireless technologies which are now on the chart for the first time.

HMS Industrial Networks now presents their annual analysis of the industrial network market. As an independent supplier of products and services for industrial communication and the Internet of Things, HMS has a substantial insight into the industrial network market. Here are some of the trends they see within industrial communication in 2016.

Fieldbus is still growing:

Looking at new installed nodes within factory automation globally, fieldbuses are still the most widely used type of networks with 58% of the market. Fieldbuses are still growing by approximately 7% per year as users ask for simplicity, tradition and reliability.

The dominant fieldbus is PROFIBUS (17% of the total world market including industrial Ethernet) followed by Modbus (7%), and CC-Link (6%).

Industrial Ethernet is growing faster than before:

According to HMS, industrial Ethernet is growing faster than previous years and taking more market shares. At a growth rate of 20%, Ethernet now makes up for 38% of the global market compared to 34% last year. EtherNet/IP is the number one Ethernet network with 9% followed by PROFINET (8%). Runners-up are EtherCAT, Modbus-TCP and Ethernet POWERLINK.

“We see evidence of an accelerated transition towards industrial Ethernet when it comes to new installed nodes,” says Anders Hansson, Marketing Director at HMS. “However, industrial automation is a conservative market and it will take time before industrial Ethernet outgrows fieldbuses.”

Wireless is coming:

For the first time, wireless technologies are on the chart with 4% of the worldwide industrial network market. WLAN is most popular, followed by Bluetooth.

“We see the Internet of Things as a big driver for wireless technologies,” says Anders Hansson. “Wireless opens up for new automation architectures and is increasingly being considered for machine connectivity and control, including Bring Your Own Device (BYOD) solutions via tablets or smartphones.”

Regional facts:

In Europe and the Middle East, PROFIBUS is the leading network while PROFINET has the fastest growth rate. Runners up are EtherCAT, Modbus-TCP and POWERLINK.

The US market is dominated by the CIP networks where EtherNet/IP is overtaking DeviceNet in terms of market shares.

In Asia, no network stands out as truly market-leading – PROFIBUS, PROFINET, Ethernet/IP, Modbus and CC-Link are widely used. EtherCAT continues to establish itself as a significant network, and there are early signs of CC-Link IE Field being adopted.

More and more devices are getting connected:

“The presented figures represent our consolidated view, taking into account insights from colleagues in the industry, our own sales statistics and overall perception of the market,” says Anders Hansson.

“It is interesting to see that industrial Ethernet is now growing faster and that wireless technologies are gaining foothold. What is completely clear, however, is that the network market remains fragmented as customers continue to ask for connectivity to fieldbus, industrial Ethernet as well as wireless networks. All in all, industrial devices are getting increasingly connected, boosted by trends such as Industrial Internet of Things and Industry 4.0. With our long-term motto ‘Connecting Devices,’ HMS is well-suited to grow with these trends.”

Courtsey HMS - Industrial Networks

The Michelin Group has awarded a four-year contract to Rockwell Automation (NYSE: ROK) that designates the industrial automation and information company as the preferred provider to all the Michelin Group’s factories worldwide.

The Michelin Group has awarded a four-year contract to Rockwell Automation (NYSE: ROK) that designates the industrial automation and information company as the preferred provider to all the Michelin Group’s factories worldwide.

Industrial Ethernet is growing faster than before and now accounts for 38% of the market. EtherNet/IP is in first place within industrial Ethernet globally, followed by PROFINET. However, classic fieldbuses are still dominating the fragmented world of industrial networks with 58% and PROFIBUS is still the most widely used industrial network. Furthermore, the Internet of Things is driving wireless technologies which are now on the chart for the first time.

Industrial Ethernet is growing faster than before and now accounts for 38% of the market. EtherNet/IP is in first place within industrial Ethernet globally, followed by PROFINET. However, classic fieldbuses are still dominating the fragmented world of industrial networks with 58% and PROFIBUS is still the most widely used industrial network. Furthermore, the Internet of Things is driving wireless technologies which are now on the chart for the first time. Schneider Electric Software, a global leader in industrial software and part of Schneider Electric, the global specialist in energy management and automation, announces that customer Fujirebio Diagnostics, Inc. was placed in the Top 10 of the 2015 Workflow Management Coalition (WfMC) Global Awards for Excellence in Business Process Management (BPM).

Schneider Electric Software, a global leader in industrial software and part of Schneider Electric, the global specialist in energy management and automation, announces that customer Fujirebio Diagnostics, Inc. was placed in the Top 10 of the 2015 Workflow Management Coalition (WfMC) Global Awards for Excellence in Business Process Management (BPM). Rockwell Automation has announced that it has agreed to purchase MagneMotion, a leading manufacturer of intelligent conveying systems. MagneMotion systems are used across a broad range of industrial applications including automotive and general assembly, packaging and material handling. This acquisition will complement Rockwell Automation’s iTRAK to create the broadest portfolio of independent cart solutions in this emerging technology area.

Rockwell Automation has announced that it has agreed to purchase MagneMotion, a leading manufacturer of intelligent conveying systems. MagneMotion systems are used across a broad range of industrial applications including automotive and general assembly, packaging and material handling. This acquisition will complement Rockwell Automation’s iTRAK to create the broadest portfolio of independent cart solutions in this emerging technology area. Information technology (IT) has permeated manufacturing infrastructure and operations, producing The Connected Enterprise and triggering questions about responsibility for plant-based networks and assets. IT and operations technology (OT) professionals are facing convergence in their duties and the skill set required to succeed. Rockwell Automation and Sunset Learning Institute (SLI) are teaming up to improve and increase access to continuing education and certifications surrounding the Industrial Internet of Things (IoT).

Information technology (IT) has permeated manufacturing infrastructure and operations, producing The Connected Enterprise and triggering questions about responsibility for plant-based networks and assets. IT and operations technology (OT) professionals are facing convergence in their duties and the skill set required to succeed. Rockwell Automation and Sunset Learning Institute (SLI) are teaming up to improve and increase access to continuing education and certifications surrounding the Industrial Internet of Things (IoT).